WORKHOLDING

Clamping technology from KIPP

Clamping technology is used in a wide range of industries where a workpiece needs to be held for machining. Highest precision has the most importance, both in terms of the actual clamping, but also the precisely timed duration in which a workpiece is to be clamped for machining before it is exchanged.

As a manufacturer of clamping technology, KIPP has decades of experience and extensive know-how. Clamping technology from KIPP that is perfectly matched to the application helps to ensure that production runs with the best possible efficiency and speed and largely without disruptions. You can find an overview of the KIPP clamping technology programme in the online shop.

With its extensive expertise in the areas of workpiece, modular, zero-point and vice clamping technology, the Baden-Württemberg-based manufacturer KIPP is one of the leading manufacturers of clamping technology.

KIPP's entire product range includes over 65,000 readily available parts. The complete range can be found in the KIPP online shop. The KIPP clamping technology programme offers a diverse range of components for universal clamping of workpieces, basic elements for modular design, systems for rapid, precise clamping and referencing using zero-point clamping technology and various types of vice.

Clamping technology from KIPP is characterised by top quality, a very good price-performance ratio and maximum precision. Further advantages: Where KIPP clamping systems are integrated into a production process, they minimise set-up times and downtimes. The machining conditions are improved and workpiece exchanges within seconds are also made possible.

KIPP clamping technology systems are modular and compatible with each other. This ensures maximum set-up time optimisation for machining tools. The most diverse clamping situations are covered with this wide clamping technology range. You can find an overview in the KIPP online shop.

Different clamping techniques and systems

The clamping technology spectrum is wide and varied. Clamping technology is adaptable and as versatile as the various production applications in which it is used. In addition to numerous standard products, KIPP also fulfils individual customer requirements in terms of selecting the optimum and most suitable clamping technology.

Clamping technology uses various processes and functions to fulfil requirements. For example, the following are used

- Mechanical clamping technology

- Pneumatic clamping technology

- Hydraulic clamping technology

Zero-point clamping systems are used to clamp workpieces quickly and easily with maximum precision. They enable high production speed and efficiency. The zero-point clamping systems from KIPP can be operated pneumatically or mechanically i.e. manually.

Zero-point clamping technology from KIPP includes systems for rapid, precise clamping and referencing. 5-axis module clamping systems are available for multi-sided machining. The various positioning and clamping systems in mechanical and pneumatic versions can also be used as quick-change systems.

KIPP's clamping technology product portfolio is modular, which means that the individual systems and clamping elements can be combined. This permits various clamping technology items from different categories to be combined with each other, so that e.g. respective workpieces can be clamped precisely.

Clamping technology: Applications and clamping systems

Clamping technology for milling

KIPP has a wide range of clamping technology for milling. The KIPPflexX 5-axis vice is a versatile solution for 5-axis milling machines and can be used as a standard vice for clamping rough workpieces or with a draw-down effect on pre-machined faces. KIPPflexX is suitable for mounting on machine tables with T-slots or tapped holes; a centre bore ensures centric alignment. The baseplate has longitudinal and transverse alignment slots. The symmetrical design means that the workpiece is always centred and with a repeat accuracy with the draw-down function of ±0.01. A wide selection of different jaw plates is available for the KIPPflexX 5-axis vice. For example, jaw plates with pins are used for clamping raw components, these impress themselves into the material, eliminating the need for time-consuming pre-embossing.

Other features of KIPPflexX:

- Support height of up to 180 mm for optimum tool accessibility on 5-axis milling machines

- Flat slides for more stability and rigidity

- Exceptionally high clamping force of 52 kN

A wide clamping range can be covered by using different adapter and extension shafts.

The KIPP clamping technology range

The versatile and wide range of clamping technology from KIPP offers the ideal products for every application. If solutions are required that go beyond the extensive standard programme, individual customer requirements can always be fulfilled, where KIPP demonstrates its extensive expertise in clamping technology. Depending on requirements, materials such as grey cast iron, stainless steel, tempered steels, aluminium or plastic are available.

Workholding technology

In the Workholding Technology category, KIPP offers a wide range of components for the universal clamping of workpieces. It is made up of logically organised product groups such as clamping elements, positioning elements and clamping accessories for machine tools. KIPP workholding technology products can be freely combined and are very flexible in their application.

Workholding technology from KIPP includes the following product families and systems:

- Clamping elements

- Locating elements

- Support and stop elements

- Form holding systems

- Workpiece stabilisers

- Chain clamps

Modular clamping technology

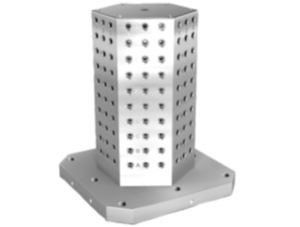

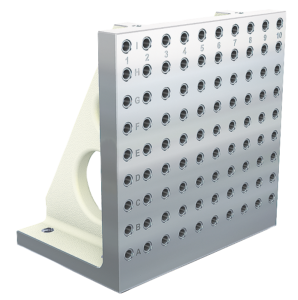

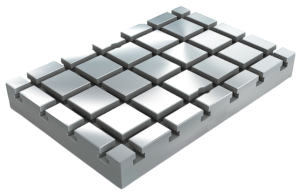

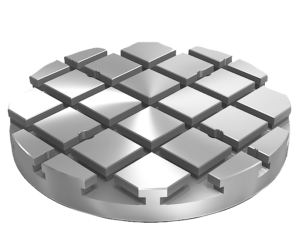

The modular clamping technology category contains basic elements for the modular assembly of components via grid holes. Standard plates, towers and angles increase flexibility and reduce the number of elements in a fixture to a minimum.

Modular clamping product families and systems from KIPP:

- Base elements

- Add-on elements

- Connector elements, accessories

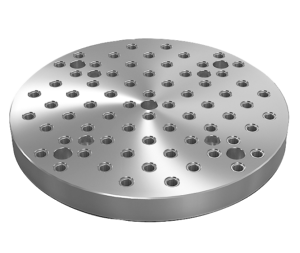

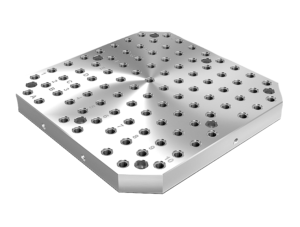

Zero-point clamping technology

Zero-point clamping technology from KIPP includes systems for rapid, precise clamping and referencing. 5-axis module clamping systems are available for multi-sided machining. Other quick-change systems are the mechanical and pneumatic positioning and clamping systems.

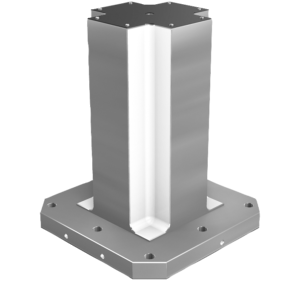

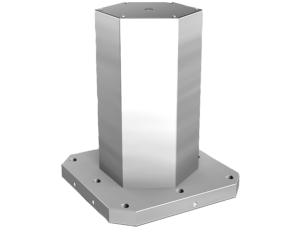

The 5-axis modular clamping system from KIPP is designed for complete machining with a single clamping operation. This guarantees maximum precision: While workpieces in machine vices often have to be repositioned, workpiece clamping with the 5-axis modular clamping system enables optimum accessibility from all sides. This reduces set-up costs, facilitates the use of standard tools and increases precision.

Thanks to the variable structure and the large number of modules, users can configure the system individually and combine it in new ways. More than 70 elements are available, including basic and add-on modules and accessories. In combination, they guarantee a variety of heights, docking onto clamping ports and machining different complex workpieces.

Zero point clamping technology product families and systems:

- Zero-point clamping systems

- 5-axis module clamping system 80

- 5-axis module clamping system 50

- 5-axis module clamping system 138

- Positioning and clamping systems

Vice clamping technology

The range of vice clamping technology from KIPP includes various vice types, such as 5-axis vices for 5/6-sided machining. The programme also includes NC vices for 3-axis milling machines as well as multi-clamping systems for large batch production. Centric vices with zero point and automation interface and stationary chucks complete the portfolio.

Overview of the KIPP vice clamping technology product families and systems:

- KIPPflexX 5-axis vice, 5-axis clamping system compact

- 3-axis vice, 5-axis vice

- Centric vices

- NC vices

- Multi-clamping systems

- Stationary chucks