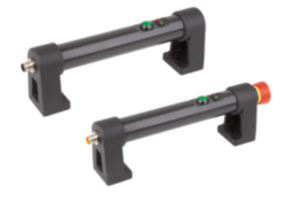

hook clamp

Notable features of the hook clamps are that they can be used in a wide range of applications and do not require much space. For example, they can be used in the construction of machines, tools and fixtures.

Hook clamps by KIPP

Hook clamps are essential tools in various industries. They are used to hold workpieces securely in place while they are being machined or assembled. The operating parts come in different shapes and sizes. This versatility makes the operating parts suitable for use in a wide range of applications.

It is therefore no surprise that clamping elements play a decisive role in various industries. Depending on the area of application, operating parts have different uses. In metal processing, for example, clamping hooks are used in machines and systems. There they hold workpieces during machining and contribute to precise positioning. They allow operators to adjust clamping force and fit workpieces according to machining requirements.

In addition to metal processing, tensioninghook clamps are also used in the following areas:

- Carpentry

- Construction industry

- Automotive industries

- Electrical manufacturing

- Tool and fixture construction

What are hook clamps?

Hook clamps for the industry

For efficiency and precision: Invest in KIPP hook clamps

Hook clamps are tools that use clamping force to hold workpieces securely in place during machining. A hook clamp consists of a body and a moving element. To generate clamping force, the moving element has a mechanism.

There are different types of hook clamps. Depending on the area of application and requirements they come in different shapes, sizes and designs. Some hooks are manually operated, while others can be operated pneumatically, hydraulically or electrically.

The functionality of a hook clamp can vary depending on type and design. In general, however, it works as follows:

The clamping element consists of a fixed body and a moving element, which is usually referred to as a clamping arm or clamping jaw. Depending on the type of hook, the tensioning mechanism can have different shapes. Generally, the clamping mechanism is actuated by a rotary movement or a lever movement.

Actuating the clamping mechanism generates clamping force that moves the movong element of the hook clamp in the direction of the workpiece.

When the moving element of the hook contacts the workpiece, it is pressed against the workpiece by the clamping force generated. This fastens the workpiece securely and holds it in place.

Some hooks have a locking mechanism or a locking device. This holds the moving element in position as soon as the workpiece is fastened. This maintains clamping force even if the clamping mechanism is no longer actuated.

To release the workpiece, the clamping mechanism is actuated in the opposite direction. This reduces the clamping force and moves the moving element away from the workpiece.

Hook clamps for the industry

Hook clamps are part of clamping elementgroup. KIPP offers a wide range of operating parts. Below, we will discuss all styles available. Besides hook clamps the category also includes operating parts that can be used in combination with the hook. The additional elements can improve the functionality of the hooks or fulfil a specific requirement. Additional elements include the following:

- Down-thrust clamps

- Compression springs

- Riser cylinders

- Hook clamp holders

Hook clamps with collar

Hook clamps with collar are made of QT steel. Thanks to its tempering and burnishing, the steel guarantees additional hardness and corrosion resistance.

The collar allows the hook to be screwed directly into a grid hole without the need for countersinking.

Suitable height adjustment elements, such as riser cylinders, can be used for optimum adaptation to different heights or requirements. These allow for the clamping height of the clamping element to be adjusted and the workpiece to be fastened precisely.

These clamping hooks with collar by KIPP are available:

- Hook clamp with collar and clamping lever with clamping force intensifier

- Standard version

Hook clamps with collar and cam lever

Hook clamps with collar and cam lever are made of different materials.

Base body and hook clamp are made of high-quality QT steel, the grip is made of cast aluminium EN AC-46200 and the pressure disc is made of plastic. The hinge pin, stud and washer are made of 1.4305 stainless steel, which offers high corrosion resistance.

As the hook can be swivelled for inserting and removing the workpieces, this style is ideal for applications in which the parts are inserted from above.

The exact clamping height can be set with the fine thread of the stud using a screwdriver. This setting can be secured with the locking screw.

Hook clamps with collar and cam lever offer a precise and reliable clamping solution for a wide range of applications. They are ideal for professional use in metalworking, woodworking and other industries.

Hook clamps with protective insert

Hook clamps with protective insert offer effective protection of surfaces of workpieces during clamping. They are made of QT steel, which is known for its strength and durability. The protective insert is made of either POM (polyoxymethylene) or polyurethane.

This style includes tempering and burnishing, which ensures additional hardness and corrosion resistance. The plastic protective insert is firmly pressed into the clamping element and offers optimum protection against damage to delicate surfaces of workpieces. This ensures that the workpiece is held securely without causing scratches, dents or any other damage.

This hook clamp is particularly suitable for applications where the surface of the workpiece is delicate and requires gentle handling. It offers an effective way to produce high-quality results without compromising on the quality of the workpiece.

Hook clamps with mounting bracket

Hook clamps with mounting bracket are a practical solution for clamping workpieces at different angles. This is particularly useful for jobs where precise angles are necessary, such as when milling, drilling or grinding workpieces.

Both clamping screw and hook clamp are made of tempered steel, which ensures reliable clamping force and a long service life. The burnished surface improves wear resistance and extends the service life of the operating part.

The KIPP product range includes two styles of hook clamp with mounting bracket:

Hook clamp with long claw clamp

Suitable when clamping workpieces with increased space requirements or inaccessible areas are hook clamps with long claw clamp. They are made of high-quality QT steel and are tempered. The tempering of the steel ensures high strength and wear resistance.

The extended claw clamp makes allows for the workpieces to be held securely, even if they protrude beyond the usual clamping dimensions or are located in areas that are difficult to access. Hook clamps with long claw clamps are versatile tools that can be used in a variety of industries and applications, from metalworking to woodworking and more. With their sturdy and high-quality design, they offer a reliable solution.

In addition to the standard version with long claw clamp the range also includes:

For efficiency and precision: Invest in KIPP hook clamps

KIPP is one of the leading manufacturer of high-quality clamping elements that help you to improve your work processes and achieve first-class results. Our ratchet levers are characterized by sturdiness, reliability and versatility and offer the precision and efficiency you need.

With a wide range of hook clamps, KIPP offers the right solution for every application. No matter whether you are in metalworking, woodworking, the construction industry or any other sector! Our operating parts are designed to fulfil your requirements.