Rod ends

Rod ends by KIPP

A rod end, sometimes called a spherical bearing or rod-end eye, is a mechanical operating part used to create a flexible connection between two parts. Rod ends enable movements around several axes and are often used in mechanical engineering applications. There they allow for movement, transmit forces and offer flexibility. Operating parts are also essential in industrial areas such as robotics, vehicle steering systems and material handling systems.

Due to their design, operating elements allow for precise motion transmission and are available in a variety of sizes and styles. Their versatility allows them to be used in a wide range of applications, from small hand-held devices to large industrial machines. Thanks to their precise control and positioning, rod ends are able to control movements accurately, which is crucial in many applications.

Operating principle of rod ends

Applications in industry

Types of rod ends

Quality standards and certifications

Advantages of rod ends by KIPP

Operating principle of rod ends

A spherical bearing consists of a rod end housing and a spherical bearing that allows rotary movement around several axes. The exact operating principle may vary depending on the specific design and application, but in general, rod ends work as follows: The rod end consists of an outer housing which is often spherically shaped. The rod end housing also has one or more openings to accommodate the spherical bearing. It is designed so that it can be firmly connected to a part of the mechanical system while the spherical bearing is mounted inside it and allows movement.

A spherical bearing located inside the rod end housing and allows for the swivelling movement of the rod end around several axes. It can have different designs, such as ball bearings or plain bearings. The spherical bearing is often designed so that it can move freely around the axes while absorbing loads and forces affecting the rod end at the same time.

A thread or another fastening element connects the rod end to the mechanical system. This allows the rod end to move while being securely attached to the system.

Applications in industry

KIPP as the manufacturer offers rod ends so that they are supplied directly from manufacturing source ensuring improved control of product quality. Our rod ends are made from high-quality materials that guarantee high strength, wear resistance and durability. Such materials are carefully selected to ensure that our products perform reliably even under demanding conditions.

The versatility of these parts permit use in a wide range of applications. Application areas include the following industries:

- Automotive: In automotive production, operating parts are used in steering linkages, suspensions and other components to enable steering and suspension.

- Machine construction: Spherical bearings are used in various mechanical engineering applications, for example in robot arms, conveyor belts and connecting mechanisms.

- Aerospace technology: In aerospace technology, the heads are used in control mechanisms, flap mechanisms and landing gear to control and transmit movement.

- Heavy industry: Here, the parts are used in applications such as cranes, conveyor belts and lifting systems to move heavy loads.

- Agriculture: Rod ends are used in agricultural machinery and devices such as tractors, combine harvesters and trailers to allow movement and transmit forces.

- Medical technology: Spherical bearings can be found in surgical instruments, medical devices and prostheses.

- Electronics production: In electronics production, operating elements are used in automation systems and robots to carry out precise movements when assembling electronic components.

Types of rod ends

The KIPP product range includes 19 different types of operating parts in the "rod end" category. Besides spherical bearings, various rod ends with rod ends or ball bearings are available.

Products consist of the following materials:

- free-cutting steel

- stainless steel

- IGUMID

- steel

- QT steel

In addition to design and material, the products differ in mounting hole and thread size. The appropriate requirements can be selected using the filter function.

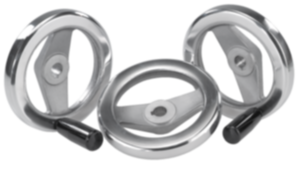

Rod ends with ball bearings

Rod ends with ball bearings are a very specific type of operating part. They enable low-friction and precise movement. The ball bearing allows for the rod end to rotate around different axes. The ball bearings ensure smooth and reliable movement. It ensures that the rod end can be moved freely and precisely without experiencing much friction.

The use of ball bearing mounted parts results in greater precision and better movement control compared to ends with other types of bearings. Therefore, the operating parts are particularly suitable for applications that require precise positioning and control.

As a manufacturer, KIPP sells two styles of ball bearing mounted spherical bearings. The main difference here is the type of thread.

- Rod end with ball bearing internal thread: The ball bearing of this operating part is long term greased with cover washers. The connection dimensions comply with DIN 648 form series KJ.

- Rod end with ball bearing external thread: The rod end with external thread is also a long term greased ball bearing with cover washers. The connection dimensions of this operating part comply with DIN 648 form series KA.

Rod ends with plain bearings

Rod ends with plain bearings are a variation in which the bearing is based on sliding elements. The sliding elements, which are often made of materials such as bronze, plastic or other lubricating materials, allow for low-friction movement of the rod end around various axes.

Compared to joints with ball bearings, the rod ends with plain bearings have a higher load rating. They are more suitable for applications involving high loads or extreme environmental conditions. By using sliding elements, rod ends can also provide improved vibration damping, making them particularly suitable for applications where vibration needs to be reduced.

Plain bearings generally require regular lubrication to ensure low-friction movement and minimize wear. However, this can be reduced by using self-lubricating materials that allow longer maintenance intervals.

Rod ends with plain bearing and internal thread

Rod ends with an internal thread have a thread inside the rod end. Due to the internal thread this allows for direct fastening to a corresponding external thread or screw. This makes installation much easier. The internal thread is available in different sizes and designs to meet the requirements of different applications.

The KIPP range includes seven different operating parts with plain bearings and internal thread:

According to DIN ISO 12240-1:

- Made of steel, maintenance free

- Made of stainless steel, maintenance free

- Made of steel, re-greaseable

- Narrow style, maintenance-free

According to DIN ISO 12240-4:

Rod ends with plain bearing and external thread

Rod ends with external thread have a thread on the outer surface of the rod end. It allows the rod end to be screwed into a corresponding nut, internal thread or other screw connection. The externally threaded parts offer a high degree of flexibility and adaptability, as they can simply be screwed onto existing screw connections or fastening elements.

The KIPP product range includes the following styles:

According to DIN ISO 12240-1:

- Made of steel, maintenance free

- Made of stainless steel, maintenance free

- Made of steel, re-greaseable

- Narrow style, maintenance-free

According to DIN ISO 12240-4:

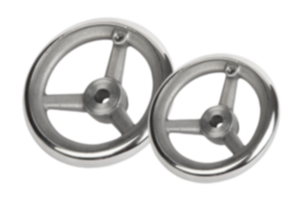

Spherical bearings

The KIPP range includes two styles of spherical bearings. The bearing shell of both spherical bearings is made of stainless steel 1.4571, while the bearing ball is made of stainless steel 1.4034.

Stainless steel has a high strength and corrosion resistance. It is hygiene-friendly and temperature-resistant.

Spherical bearings by KIPP are excellent for use in case of dynamic loads under high pressure. A distinction is made between the styles according to the dimensional series.

Spherical bearings are available in dimensional series E and dimensional series K in different heights and with different fixing holes. Both dimensional series comply with DIN ISO 12240-1.

Quality standards and certifications

Rod ends by KIPP are characterized by a number of quality features. These make a rod end by KIPP the top choice for mechanical and plant engineering. Highly important to KIPP attaches during production:

- High-quality materials: KIPP only uses high-quality materials in the manufacture of its rod ends. This not only guarantees a long service life, but also high strength and wear resistance.

- Precise design: Our operating parts are developed and manufactured with the highest precision to ensure reliable motion transmission and accurate function.

- 'Versatility: With a wide range of different styles, fastening holes and threads, spherical bearings by KIPP offer a high degree of versatility. As a result rod ends fulfil the requirements of different applications.

- Certified quality: Rod ends by KIPP meet stringent quality standards and are often certified to standards such as ISO 12240 to ensure the highest levels of quality and performance.

Choosing rod ends that meet the highest quality standards and have the corresponding certifications is crucial to the success and safety of your applications in mechanical and plant engineering. At KIPP, we understand the critical role that quality standards and certifications play. To us it is therefore extremely important to offer products that meet these standards.

Quality standards and certifications guarantee that our rod ends have undergone strict quality controls. They ensure reliability, durability and performance of products.

In addition, quality standards and certifications offer you the certainty that our spherical bearings have been tested and approved with regard to material quality, manufacturing processes, safety aspects and environmental compatibility. This is particularly important in industries where safety and quality are top priorities.

KIPP products are tested according to DIN ISO 12240. DIN ISO 12240-1 and DIN ISO 12240-4 are specific sections of the DIN EN ISO 12240 series of standards that deal with rod ends and spherical bearings. These standards define the requirements for rod ends and provide test methods as to how to determine their performance and reliability.

DIN ISO 12240-1 defines the requirements for rod ends with internal threads, while DIN ISO 12240-4 specifies the requirements for spherical bearings with flanges and rod ends with external threads.

Advantages of rod ends by KIPP

Rod ends by KIPP offer outstanding quality and reliability for different applications in mechanical and plant engineering. Due to precise design and manufacture, they guarantee accurate motion transmission and high mechanical performance. Our wide range of products allows customers to choose the perfect product for their specific requirements. KIPP spherical bearings are easy to install, reducing time and labour costs. They are durable and suitable for demanding environments.

If you need rod ends, KIPP offers a premium selection of high-quality products. Our operating parts are noteworthy for precise design and reliability. We offer a wide range of sizes, styles and materials to meet the varying requirements of different applications. At KIPP, we focus on continuous innovation and invest in research and development to steadily improve performance of our rod ends.

Are you looking for quality, reliability and top service? Then the rod ends by KIPP are the right choice for your requirements!