Latches

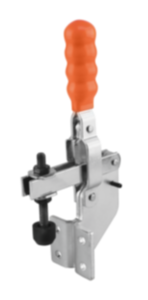

Latches are used as simple locks for covers, cladding and containers in machine, plant and container construction. The clamping stroke exceeds the dead center point, which makes them able to withstand vibrations.

Latches by KIPP

Latches are mechanical devices and are part of the group "operating parts". They are used for joining, connecting, securing or locking objects. Latches make everyday work easier, especially when temporary or repeatable opening, closing or fastening is required. They come in different shapes and sizes and are used in various applications and industries.

The application areas are diverse and range from packaging systems and industrial fasteners to vehicles and machine construction. In every application, latches provide secure and reliable fasteningthat can be easily released or opened as required.

What is a latch?

Different types of latches

Overview of the various latches by KIPP

Selection criteria and materials for latches

Advantages of KIPP latches

What is a latch?

A latch is a key component in fastening technology that is used to securely connect, affix or lock components.

KIPP latches are precisely designed mechanical operating parts, the composition of which varies depending on type and intended use. In general, these locking devices consist of several key elements.

- The housing: forms the basic structure of the latch. It serves as the base to which the various components are attached and forms the outer shell that protects the inner mechanism.

- The latching mechanism: is the key element of the latch. It varies depending on the latch type. The purpose of this part is to create a firm connection between the parts being secured.

- A locking mechanism: may also be present to secure the position of the locking mechanism and prevent unintentional disengagement. The latch mechanism ensures a sturdy and reliable connection. This is particularly advantageous in applications where vibrations or shocks can occur.

The materials of the latching device play a decisive role. High-quality steels and stainless steels ensure durability and resistance to external influences. In addition, seals or covers may be provided to protect the internal mechanism from dust, moisture or other environmental influences. This contributes to long-term functionality and maintenance-free operation of the latch.

The versatility of latching devices make them an important component in many industries, as they provide an effective way of retaining or attaching parts securely while ensuring flexibility of use.

Different types of latches

KIPP offers an impressive range of latches to meet the most diverse requirements. From latches with a spring clip to latches with covered fastening holes. The KIPP range is broad in order to flexibly respond to various applications.

Overview of the various latches by KIPP

The KIPP range includes twelve different types of latch.

Latches with draw bail

A latch with draw bail is a special latch that uses a bracket as the central element in its latching mechanism. In contrast to a classic latch, this option features a bracket that is responsible for tightening and loosening. This is why this type of latch is used in various areas, especially in situations where quick and adjustable latching is required.

Stainless steel latches

Stainless-steel latches are used in various applications when there are special requirements as to durability, corrosion resistance and an aesthetic appearance. The use of stainless steel latches is often determined by their high resistance to corrosion and chemicals as well as their strength and durability. Stainless steel latches are items according to DIN 3133.

In addition to the classic stainless steel latch, KIPP also offers a stainless steel latch with release mechanism. The surface of the latches is satin finished. The operating parts have simple latching technology and are ideal for covers, claddings and containers. Latches with release mechanism are used in machine, plant and container construction.

Adjustable latches

The adjustable latch offers the possibility of adjusting tension or the degree of securement as required. This type of latch is used in various applications where flexibility and adaptability is required. The adaptability of adjustable latches offers a practical solution in different situations to modify strength or tension of the fastening.

In addition to the classic adjustable latch, KIPP also offers following product types:

- Latches with visible fastening holes

- Latches with hidden fastening holes

- With swing bails

- For heavy loads

Latches with draw bail

A characteristic feature of latches with draw bails is its adjustability. By moving the bracket, tension or strength of the fastening can be adjusted to suit requirements of the respective application. The draw bail enables quick fastening and release of the latch, making it particularly efficient in applications where repeated and quick fastening is required.

Selection criteria and materials for latches

The selection of a suitable latch depends on various factors. These factors vary depending on the application, environment and specific requirements. By carefully considering the selection criteria, the best possible solution can be found for your individual needs and requirements.

The ability of the latch to bear the required load or stress is extremely important. The load rating should meet the specific requirements of the application to ensure secure and reliable fastening.

The desired actuation mechanism may vary depending on the application. Bails, hooks and other latching mechanisms offer varying degrees of ease of use, fastening speed and security.

The robustness of the locking mechanism is also an important criterion when selecting a latch. Environmental conditions such as temperature, humidity, chemical influences or UV radiation can vary greatly depending on the location. It is important to ensure that the latch selected can withstand environmental conditions and maintain its function.

Choosing the appropriate material for the latch is crucial. Stainless steel is often favoured for its corrosion resistance, while steel is tough and resilient. The choice of material should be based on the specific requirements of the application. The manufacture of KIPP latches in stainless steel and steel takes into account factors such as load capacity, environmental influences and areas of application.

Advantages of KIPP latches

KIPP latches stand for maximum precision and first-class workmanship.

Made from high-quality materials to ensure a long service life. Our wide range of latches can be customize to suit different applications and areas of use.

With KIPP latches, you don't just get a product, but a customized solution for your fastening requirements. Find out how KIPP can optimize your industrial processes with innovative latches.