Magnets

Industrial magnets by KIPP

KIPP offers a wide range of different industrial magnets. A distinction is made between several types e.g. pot magnets, round magnets, retention magnets or raw magnets. Depending on the style, they are particularly heat-resistant, have a high magnetic force or are extra strong permanent magnets. If you are unable to find the appropriate magnet in our range, please contact us for an individual solution. Select the appropriate solution for your application!

Depending on the type of magnet, a distinction can be made between shielded and unshielded systems. In unshielded systems, the magnetic core is exposed on all sides and is not covered by any non-magnetic layer. As a result, the magnet can deploy its full magnetic force on all sides. Shielded systems, on the other hand, cover the magnetic core with a layer of non-magnetic material. This allows the magnetic force effect to deliberately be directed in a specific direction.

Properties of industrial magnets by KIPP

There are various types of industrial magnets. They are made of different materials and have properties that are typical for respective material. With its wide selection of permanent magnets, KIPP offers products with different temperature stability, magnetic force and corrosion resistance.

Material options for magnets

Since each material has certain properties, it is advisable to select respective magnet according to the application area and use.

Neodymium magnets (NdFeB)

Neodymium-Iron-Boron magnets (NdFeB), or neodymium magnets for short, are currently the strongest permanent magnets available on the market. In addition to their high magnetic force, they are characterized by a high retaining force. The drawbacks of neodymium magnets are their low corrosion resistance and low temperature stability. As a result, neodymium magnets are mainly suited for applications with low temperatures.

Samarium-Cobalt Magnets (SmCo)

Samarium-Cobalt (SmCo) magnets consist of a samarium/cobalt alloy. They have the highest magnetic force after neodymium magnets. The retaining force is three to five times higher than that of AlNiCo magnets or hard ferrite magnets. Due to the high corrosion resistance, no separate surface treatment is necessary. However, low mechanical strength means that samarium-cobalt magnets break more easily and are therefore not suitable for applications with high mechanical forces.

Aluminum-Nickel-Cobalt magnets (AlNiCo)

Magnets made of an aluminum-nickel-cobalt alloy (AlNiCo) are characterized by their high temperature stability and the associated heat resistance of up to 450 °C. They also have high mechanical strength, which makes them perfect for applications with high mechanical forces. However, it should be noted that the retention forces of AlNiCo magnets are comparatively weak.

Hard ferrite magnets

Hard ferrite magnets consist of iron oxide and barium carbonate or strontium carbonate. This guarantees an above-average corrosion resistance and high temperature stability. As a result they can be exposed to temperatures of up to 200 °C. However, the comparatively low magnetic force and mechanical strength must be taken into account when selecting the application area.

Magnets: Types and shapes

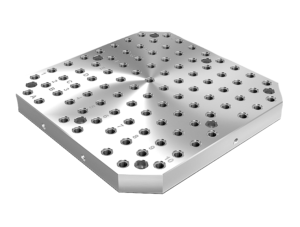

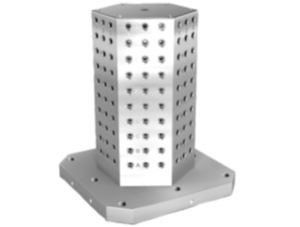

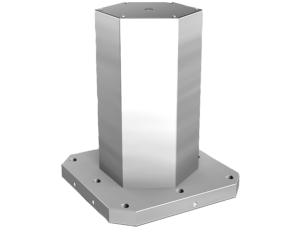

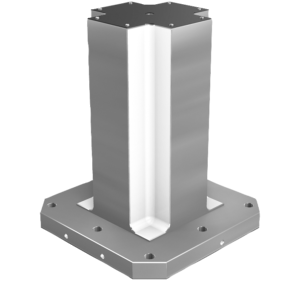

Raw magnets

Raw magnets always constitute an unshielded system. All of the permanent magnet's surfaces exert a magnetic force. Consequently, raw magnets can be integrated into magnet systems or individual applications such as housings etc. as desired. Raw magnets are used, among other things, in machine tools and mechanical engineering, in aerospace and the automotive industry. KIPP has various types and shapes of raw magnets in its range. Available magnets made from neodymium are disc form magnets with hole, disc form magnets without hole and flat, square block magnets. The magnets are electro zinc-plated and can be mounted by press-fit or gluing. The models featuring a hole can also be screwed down. Raw magnets made of neodymium can be used up to a temperature of 80 °C. Raw magnets made from AlNiCo are also available. Included in the range are round bar magnets with untreated surfaces, as well as button magnets and horseshoe magnets, all painted red. They are characterized by their high temperature range of up to a maximum of 450 °C. The surface does not require any finish due to the good corrosion resistance and they are installed by press-fit or gluing.

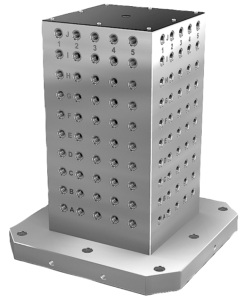

Deep pot magnets

Deep pot magnets have a core made of a permanently magnetic material. This core is separated from the housing by a non-magnetic material and a magnetic shielded system is created. KIPP deep pot magnets are used in e.g. mechanical engineering and metalworking industries as well as in electrical technology and the automotive industry.

Deep pot magnets with samarium-cobalt cores have a brass housing and are available either without or with an internal thread. They are constructed as a sandwich magnet system. These are two individual permanent magnets with a separating layer in between. To prevent loss of magnetic force due to a magnetic short circuit, these round magnets with a samarium-cobalt core must not be pressed directly into iron. As no demagnetisation occurs, SmCo deep pot magnets are particularly suitable for direct use with spot welding machines. The KIPP range includes deep pot magnets with a neodymium magnetic core as magnets with a machinable magnetic face and standard versions without a machinable magnetic face. The machinable magnetic face enables deep pot magnets to be customized to your needs. Both models feature a brass housing and are also constructed as a sandwich magnet system. Permanent magnets with a solid neodymium core must also never be pressed directly into iron.

This is to prevent a magnetic short circuit and the associated loss of magnetic force.

Deep pot magnets with an AlNiCo magnetic core and steel housing are available for applications where a certain fit tolerance is required. They can be used at temperatures of up to 450 °C. Installation is carried out by press-fitting, gluing or shrink-fitting.

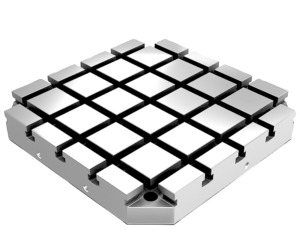

Shallow pot magnets

To achieve a shielded system, the magnetic core material is pressed or cast into a housing. There is a non-magnetic barrier placed between the magnet and the housing. Shallow pot magnets by KIPP are used in e.g. mechanical engineering, the automotive industry and metalworking industries.

Shallow pot magnet cores made of samarium cobalt have the advantage of having three to five times the magnetic force of hard ferrite or AlNiCo cores. KIPP offers Samarium-Cobalt-shallow pot magnets as magnets with a countersunk hole and electro zinc-plated steel housings, or as magnets with a counterbore and stainless steel housing. Both models can be used at high temperatures.

Installation is carried out by gluing, screwing or press-fitting.

Shallow pot magnets or flat magnets made of neodymium are available in various styles. With hooks, internal thread, counterbore, threaded pin or shallow pot magnet with tapped bush. Thanks to the permanent magnetic material neodymium, the magnetic force is 10-20 % higher than that of SmCo magnets.

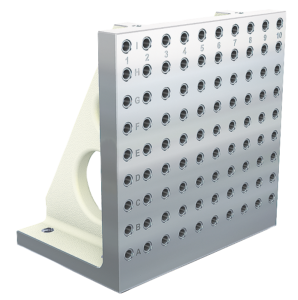

Magnets with rubber protective jacket

To protect sensitive surfaces, KIPP offers magnets with a protective jacket made of rubber. Rubber protective jackets are made of TPE or synthetic rubber. Areas of application include machine construction and electrical engineering.

KIPP sells rubber-coated neodymium magnets from the shallow pot magnet group. Available are round magnets with a hole, internal thread, threaded bush and threaded pin. In the flat square version there are magnets with internal thread and rubber protective jacket. Deep pot magnets with rubber-coated magnetic faces are also available. Due to the threaded pin, this model is a screw-on-magnet with stainless steel housing. Rubber protective caps can also be purchased at later date to retrofit existing shallow pot magnets.

Retaining magnets

Round retaining magnets by KIPP consist of a magnetic hard ferrite core surrounded by an ABS

plastic jacket. Due to their structure, retaining magnets are particularly suitable for use on thin sheet metal such as flipcharts, whiteboards or pinboards.