Cam-action indexing plungers

Cam action indexing plungers can be used for all types of locking and fixating mechanisms, especially where the indexing pin must not be allowed to protrude. The lock is released by turning the grip 180°.

Lock grips and cam-action indexing plungers by KIPP

Locking mechanisms play an essential role in safety technology and are crucial in many commercial facilities. They serve as physical barriers that secure doors, windows, gates and other openings. The most common types include cam-action indexing plunger and barrel slide bolt, each providing specific functions and advantages. Cam-action indexing plunger are sturdy, easy to use and impress with their versatility. Barrel slide bolts, on the other hand, often offer additional security functions and are frequently used in more complex security systems.

What are cam-action indexing plungers?

Locking mechanisms by KIPP

KIPP as the manufacturer of cam-action indexing plungers and barrel slide bolts

What are cam-action indexing plungers?

Cam-action indexing plungers are mechanical locking elements used to fastened or secure moving parts. They usually consist of a grip and an indexing pin. Cam-action indexing plunger are used to prevent any change in locking position due to lateral forces. Turning the dead bolt through 180° retracts the indexing pin, enabling a change in the indexed position. The notch ensures that the dead bolt remains in this position and the indexing pin remains retracted.

Cam-action indexing plunger have three main functions:

- Fixating: They prevent parts from moving and hold them in a fixed position.

- Locking: They ensure that parts cannot be moved unintentionally.

- Positioning: They allow for precise adjustment and fastening of machine components.

The areas of application for cam-action indexing plunger include mechanical engineering, the construction industry, the chemical and pharmaceutical industry as well as logistics and transport.

When selecting cam-action indexing plungers, you should note the following technical data:

- Grip length

- Locking diameter

- Material

- Locknut

Depending on model and application handle length varies and can range from 25 mm to 51.6 mm. The diameter of the cam-action indexing plunger, which engages the hole, can also vary. Typical diameters range from 4 mm to 12 mm.

Cam-action indexing plunger by KIPP are made of many different materials. Through the filter option on the side you are able to choose between aluminum, stainless steel, brass, steel and zinc. The filter option also allows you to sort by cam-action indexing plunger with or without locknuts.

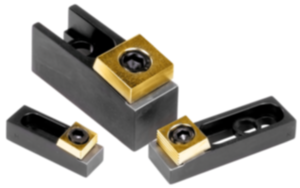

Cam-action indexing plungers with internal guide

Cam-action indexing plunger with internal guide are characterized by particularly precise guidance of the indexing pin within a housing. The special design allows for precise positioning and fastening of parts, as the pin always remains in the intended guide and cannot deflect sideways. At KIPP, cam-action indexing plunger with internal guide are available in both steel and stainless steel.

Cam-action indexing plungers made of steel with internal guide offer high strength and are affordable. They are more suitable for indoor applications or in non-corrosive environments. Dead bolts with stainless steel internal guides offer excellent corrosion resistance and are ideal for use in damp or corrosive environments, such as in the food industry or outdoors.

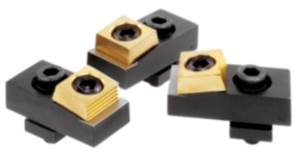

Cam-action indexing plunger with stop

Cam-action indexing plunger with stop feature an in-built stop. The KIPP locking bolts have a 180° stop. This prevents further rotation and therefore the indexing pin from being extended unintentionally. The direction of rotation of the dead bolt is determined by the side of the stop (left or right).

Cam-action indexing plungers with stop are particularly useful in applications where exact positioning is crucial, such as assembly of machines or devices.

These types of cam-action indexing plungers are also available made of different materials. Cam-action indexing plungers made of stainless steel as well as the one made of steel feature colorful bolt caps.

Cam-action indexing plungers with colorful bolt caps

Besides functional advantages cam-action indexing plungers with colorful bolt caps offer a visual component. The colored caps make it easier to distinguish and identify the cam-action indexing plunger, this being particularly advantageous in complex machines and systems. They allow easy visual inspection and contribute to work safety by clearly labelling important locking points.

Cam-action indexing plungers with colorful bolt caps are available made of different materials and in different colors. Bolt caps are made of thermoplastic (PA). Cam-action indexing plungers itself may be made of steel or stainless steel.

Our material overview will provide you with all relevant information on individual materials such as thermoplastic (PA), steel or stainless steel.

CLICK FOR MATERIAL OVERVIEW à Should be displayed as a button

Other locking mechanism by KIPP

Besides the large number of cam-action indexing plungers, the KIPP range also includes two other products in this category.

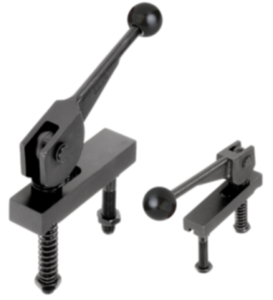

- Barrel slide bolts

- Dead bolts with return spring

KIPP barrel slide bolts feature a spring-loaded compressor that ensures secure and reliable locking. The housing is made of sturdy die-cast zinc and painted silver. The paint finish provides additional protection against environmental influences. The handle, underlays and groove fixings are made of durable thermoplastic (PA) and come in a contrasting black color.

The bolt is made of high-quality stainless steel and is bright. The choice of material ensures high corrosion resistance and longevity of the barrel slide bolt.

The barrel slide bolt is easy to install on both smooth surfaces and textured profiles. It combines functionality with durability, making it an ideal choice for a wide range of applications.

The scope of delivery includes all necessary components for various types of mounting:

- Two underlays for mounting on level surfaces.

- Two slot fixings for mounting on slotted profiles (suitable slot width of 8 mm or 10 mm).

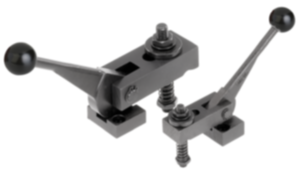

A dead bolt with return spring is characterized by its built-in spring. The return spring automatically returns the dead bolt to its original position. These dead bolts can be easily screwed onto doors, flaps and covers. The KIPP product range offers three different dead bolts with return springs:

- Dead bolt with return spring and aluminum bolt to the left or right (for doors opening to the left or right)

- Dead bolt with return spring made of steel or brass

- Dead bolt with return spring made of stainless steel

The latter two options are bevelled either upwards or downwards. The angled surface facilitates closing or opening the application without having to operate the dead bolt manually. This means that the door or hatch is closed by simply pushing it shut and the bevelled edge ensures that the dead bolt engages automatically. When the lever is pushed, the dead bolt moves into the open position so that the door can easily be opened. As soon as the door is closed again, the built-in spring takes over the task of returning the dead bolt to its locked position, ensuring reliable and secure locking.

You need additional information about individual materials?

KIPP as the manufacturer of cam-action indexing plungers and barrel slide bolts

KIPP stands for quality and reliability. Our products are made of high-quality materials and offer a long service life. Innovative designs and easy handling of our locking mechanism make them the perfect choice for numerous applications. You can trust in KIPP's experience and expertise to fulfil your locking requirements. Our locking mechanism are versatile and suitable for all types of fastening. Cam-action indexing plunger are optionally available with colored plastic bolt caps, allowing applications to be easily identified by color. This not only increases functionality, but also security and user-friendliness. Simple installation and operation of the dead bolts make them the perfect choice for a wide range of applications.