Toggle clamps

Toggle clamps are intended for assembly and clamping fixtures and are used in machine construction, metalworking and woodworking. Due to their slim design, toggle clamps can be easily integrated into tight spaces.

Toggle clamps by KIPP for mechanical engineering

Toggle clamps for mechanical engineering are specific devices used in metalworking and machine construction industries.

They secure and fasten components, workpieces or entire fixtures. Toggle clamps are designed to enable parts to be exchanged quickly and easily without the need for time-consuming manual adjustments or tool changes.

This may be required during manufacturing processes, assembly work or other machining stages to ensure precise positioning and secure fixation of parts.

What are industrial toggle clamps?

Operating principle of toggle clamps

The importance of toggle clamps in the industry and mechanical engineering

Types of industrial toggle clamps

Toggle clamps with force sensor

Applications for toggle clamps in mechanical engineering and the industry

Toggle clamps by KIPP

What are industrial toggle clamps?

Toggle clamps are indispensable tools in mechanical engineering and the industry. They are used to securely clamp movable components. These ingenious devices operate on a double lever principle. The are designed to be easy to operate.

How a toggle clamp works is clear to see:

- Toggle clamps allow for quick and simpleclamping of workpieces or fixtures. This reduce setup times and increases productivity.

- Toggle clamps are often equipped with safety mechanisms to prevent unintentional release and ensure safety in the workplace.

- High quality toggle clamps offer high precision and repeataccuracy when clamping objects. This is particularly important when it comes to demanding machining processes.

- Toggle clamps are available in various shapes and sizes to meet the different requirements in metalworking and mechanical engineering. They can be mounted horizontally, vertically or in other orientations.

- Some toggle clamps have built-in force sensors that monitor the clamping force applied and ensure that the components are secured firmly enough without causing damage.

In summary, toggle clamps are used in mechanical engineering to optimise the manufacturing process, increase efficiency and improve the quality of the manufactured parts. Choosing the best toggle clamp depends on the specific requirements of the application in question.

Operating principle of toggle clamps

Toggle clamps consist of a lever that actuates a clamping arm via a toggle mechanism. When the lever is actuated, the long travel of that lever is converted into a short travel on the clamping arm. In doing so, the so-called lever dead centre is exceeded, whereby the clamp locks securely.

The result is reliable clamping of the workpiece at its clamping location. The retaining force is a characteristic value for each toggle clamp and depends on the size of the clamp and the position of the thrust screw along the clamping arm.

The importance of toggle clamps in the industry and mechanical engineering

Toggle clamps are of crucial importance in many industries. They are used to effortlessly and precisely clamp components, while increasing productivity and improving the quality of the manufactured parts.

Toggle clamps are particularly indispensable in mechanical engineering, metalworking and the automotive industry. They enable rapid tool changes,shorten setup times, and contribute to increased efficiency.

Here are some of the most common uses for toggle clamps in mechanical engineering:

- Secure clamping of workpieces during machining processes such as milling and drilling. This leads to precise and stable machining.

- On CNC machines and production lines, toggle clamps are used on quick-change tool holders for light cutting tools. They reduce setup times and increase efficiency.

- The clamping of fixtures required to position workpieces. This allows for repeatability of work processes.

- In plastics processing and injection moulding, toggle clamps are used to secure moulds and tools for the production of plastic parts.

- Toggle clamps are also used in the maintenance and repair of machines to provide access to certain areas and securely attach components.

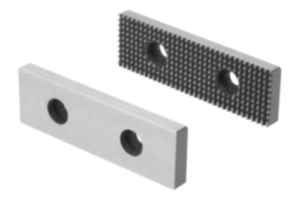

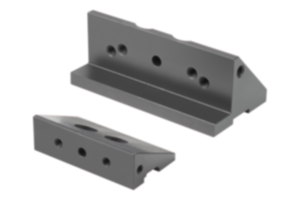

Types of industrial toggle clamps

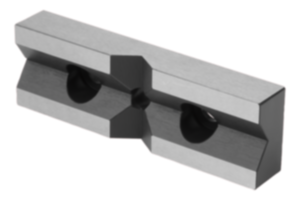

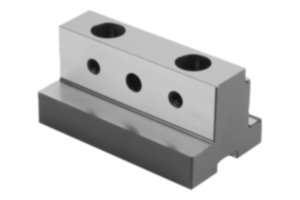

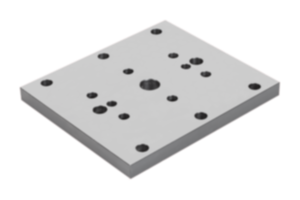

KIPP toggle clamps are available in stainless steel and steel. The foot of the toggle clamp is available as a vertical, horizontal and angled versions. In the KIPP range, toggle clamps are divided into different styles.

The following styles are available:

- antistatic toggle clamps

- toggle clamps with safety interlock and force sensor

- mini toggle clamps

- toggle clamps with force sensor

- toggle clamps with safety interlock

- heavy-duty toggle clamps

- With standard toggle clamps the clamping lever is horizontal when in the clamped position. (horizontal lever position)

- With vertical toggle clamps the clamping lever is vertical when in the clamped position. (vertical lever position)

Toggle clamps with force sensor

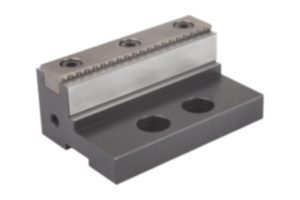

Toggle clamps with force sensors are special devices used in mechanical engineering and the industry to clamp components or workpieces with a precise and monitored clamping force.

With conventional toggle clamps, the clamping force is set manually. In contrast to these, toggle clamps with a force sensor are fitted with an integrated sensor. The sensor offers the possibility to precisely adjust theclamping force, to measure and monitor it. This function permits workpieces to be clamped in a defined manner, which enables traceability and control of the clamping force

The clamping element plays a central role in adjusting clamping force. Depending on requirements, different heights of clamping elements are available to securely and efficiently clamp workpieces of different thicknesses. This flexibility ensures that toggle clamps can be used in a variety of applications where workpieces with varying thicknesses need to be held in place.

The key features and functions of toggle clamps with force sensor are:

- Precise clamping force control: The integrated force sensor enables precise monitoring of the applied clamping force. This is particularly important in applications where an exact clamping force is required to hold components securely and precisely.

- Safety: Continuous monitoring of clamping force ensures that components are not overstressed, which prevents damage and guarantees safety in the workplace.

- Real-time feedback: Toggle clamps with force sensors provide real-time feedback on the current clamping force, which can then be displayed on digital displays or in machine control systems. This enables operators to monitor the clamping status at all times.

- Adaptability: The desired clamping force can be easily set and adjusted depending on the application requirements. This enables versatility in the use of toggle clamps with force sensors.

- Prevention of errors: The ability to accurately monitor and control clamping forces minimises human error and ensures consistent results.

The KIPP range includes two different Toggle clamps with force sensor.

- Stainless steel horizontal toggle clamps with force sensor

- Stainless steel horizontal toggle clamps with safety interlock and force sensor

Toggle clamps with force sensors are used in various industries, especially in sectors where high precision and repeatable processes are crucial.

Examples of such applications include the machining of precision parts in metal processing, the production of electronic assemblies and the automotive industry. The use of toggle clamps with force sensors helps to improve production quality and increase efficiency.

Applications for toggle clamps in mechanical engineering and the industry

The application areas for toggle clamps are diverse and they are used in various sectors. They are used in metalworking, the automotive industry, aerospace, electronics manufacturing, machine construction and many other areas.

There are also numerous industrial applications. Industrial toggle clamps are used wherever components or workpieces need to be clamped securely and efficiently in order to streamline processes and increase productivity.

In the automotive industry, toggle clamps are used on the assembly line to e.g. precisely position components such as bodywork elements.

Toggle clamps enable food to be processed quickly and hygienically in the foodstuff industry. In the aerospace industry, they ensure the precision and safety of assemblies and components.

Toggle clamps by KIPP, a good choice

When buying toggle clamps, quality and reliability are crucial. KIPP toggle clamps are characterised by their precision, durability and safety.

If you would like to know more about our toggle clamps or have any questions, please contact us. Our team will be happy to help select the best toggle clamp for your application.