Cam levers

Cam levers are ideal for quick fixation. The products are available in various materials and colors. They are used in machine and plant construction, in toolmaking, and in medical and rehabilitation technology.

Cam levers by KIPP

An cam lever is perfect for quick and torque-free fastening or clamping operations. It consists of a lever that rotates around an eccentrically mounted axle. Thanks to this eccentric bearing, the lever generates a force when actuated that is sufficient to securely fasten or clamp a workpiece.

One advantage of cam levers is their availability in different materials and colors. Therefore, they can be adjusted to specific requirements and that not only makes them functional, but also flexible when it comes to the design of machines and devices. The ability to easily create a strong and secure connection emphasises the importance of cam levers in up-to-date technology. They significantly contribute to the improvement of processes, safety and reliability in different application sectors.

The levers are widely used in areas such as mechanical engineering, toolmaking and plant engineering. Their ability to quickly and safely carry out fastening and adjustment processes makes them an efficient solution for many industrial and technical tasks.

What are cam levers?

Advantages of cam levers

Choosing the right cam lever

KIPP: Your manufacturer of cam levers

What are cam levers?

Cam levers are operating parts that are used for quick and torque-free clamping of workpieces. It uses an eccentrically mounted axle to generate sufficient clamping force when actuated. This property makes it a versatile tool in many technical and industrial applications.

Cam levers consist of the following main components:

- Lever arm: The lever arm is the main part of the cam lever. It serves as a handle and facilitates power transmission. It is made of a sturdy material such as steel or plastic and can be ergonomically shaped to make handling easier. The clamping force is generated by moving the lever arm.

- Eccentric axle: An eccentric axle is an axle that is mounted off-centre in the lever. It enables the actual clamping or fastening movement and is therefore the centrepiece of the cam lever. This off-centre axis converts the rotary movement of the lever arm into a linear movement that moves the clamping plate towards or away from the workpiece.

- Bearing or pivot point: The pivot point is the area around which the lever arm moves. Bearings are often built-in to enable low-friction movement. The pivot point enables the lever arm to rotate and supports the eccentric axis to precisely carry out the movements.

- Clamping plate: A clamping plate is that part of the cam lever that presses directly onto the workpiece. It can be made of metal, plastic or other materials and often has a non-slip surface. The clamping plate transfers the generated force to the workpiece and holds it securely against the counter bearing.

For a cam lever to work designed, the lever arm has to be actuated. This sets the eccentric axis in motion. The of-centre mounting of the axle converts the rotary movement of the lever arm into linear movement. This linear movement of the eccentric axis causes the clamping plate to move towards the workpiece. The clamping plate presses the workpiece against the counter bearing, ensuring that it is securely fastened. If the lever arm is moved in the opposite direction, the clamping plate retracts from the workpiece and fastening is released.

Advantages of cam levers

Cam levers offer numerous advantages that make them a firm favourite for many an industrial and technical application. One of the biggest advantages is the variable force transmission, which, depending on requirements and application, enables the generation of different clamping forces. This makes cam levers extremely flexible and adaptable. The compact design of the levers ensures easy use in confined working areas without needing much space.

Another outstanding feature is the smooth movement and high force amplification achieved by the of-centre mounting of the axle. This ensures reliable and constant clamping force each time the lever is operated. Cam levers are also characterized by long service life and easy maintenance. The sturdy design and use of high-quality materials ensures that the levers remain operational for a long time, even under demanding conditions, and ca easily be serviced or replaced if necessary.

Especially cam levers by KIPP offer additional advantages. They are available with internal and external thread in various thread sizes. This ensures high compatibility with different applications and requirements. The use of high-quality materials in the manufacture of KIPP levers contributes to their durability and reliability, which in turn extends usability of the parts. In addition, the design of cam levers allow for easy maintenance and replacement, which reduces operating costs and increases efficiency in use..

Choosing the right cam lever

Selecting the right cam lever is crucial for optimum performance and durability in the respective application. Various factors should be taken into account when selecting the lever to ensure that it meets specific requirements. Factors such as:

- Size

- Load capacity

- Thread type and size

- Material

The size of the cam lever is a fundamental factor that depends on the application and the space available. A lever that is too large could be inconvenient in confined spaces, whilst one too small may not provide the necessary clamping force. It is important to precisely match the dimensions of the lever to the requirements of the application. The length of the lever arm should also be taken into account, as it directly influences leverage and achievable clamping force.

The load capacity of the eccentric lever has to meet the requirements of the application. Static as well as dynamic loads that can occur during operation must be taken into account. It is important to know the maximum clamping force that the lever has to exert on the workpiece and to ensure that the selected lever can withstand this force without deformation or damage. The manufacturer's specification on maximum load capacity and safety factors have to be complied with.

Compatibility with existing systems and components is important. Cam levers are available with internal or external thread to allow for flexible adjustment. You can feely choose between thread sizes M3 right through to M10. The KIPP cam levers are also available in different thread lengths, ranging from 10 mm to 50 mm.

The material of a cam lever also influences both load capacity and service life of the lever. Commonly used materials are steel, stainless steel, aluminium and polyamide. Steel and stainless steel offer high strength and corrosion resistance, making them ideal for use in demanding environments. Aluminum is lighter and can be advantageous in applications where weight is an issue. The choice of material should be based on the specific environmental conditions and mechanical requirements. Our material overview provides you with a more detailed description of each individual material.

The filter option allows you to filter individual cam levers according to these factors. Here you'll find individual operating parts sorted by material:

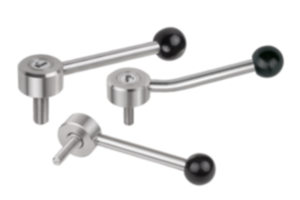

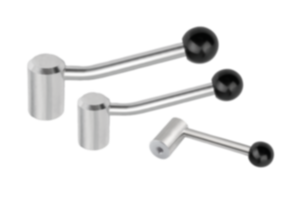

- Cam levers made of aluminum

- Cam levers made of stainless steel

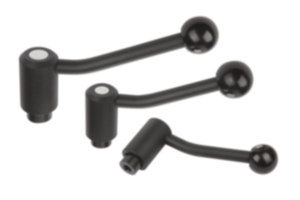

- Cam levers made of polyamide

- Cam levers made of steel

Aluminum and polyamide levers can be purchased with base body in different colors. Colors make it easy to distinguish between the cam levers.

KIPP: Your manufacturer of cam levers

KIPP is one of the leading manufacturers in clamping technology, standard elements and operating parts. With many years of experience we stand for outstanding quality, innovation, and reliability. KIPP products are used in numerous industrial sectors and are known for their durability and precision.

A particular highlight of the KIPP product range are cam levers. The levers are specifically designed to generate strong and precise clamping force by utilising an eccentric rotary movement. They are perfect for applications that require fast and secure fastening, such as in the machine tool industry, in plant engineering or assembly technology.

Why buy cam levers by Kipp?

KIPP products are known for their first-class workmanship and reliability. Cam levers are made of sturdy materials and are subject to strict quality controls to ensure that they meet the highest standards.

We offer a wide range of cam levers in different designs, sizes and materials. This allows you to find exactly the right lever to suit your specific requirements.

Discover high-quality cam levers by KIPP and experience their quality and performance first hand.