Material

Wire cable stainless steel.

Sheath, steel wire with inner and outer plastic coating.

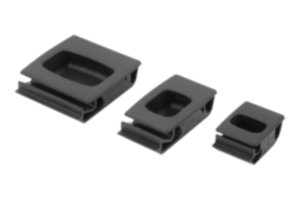

body POM.

Nipple Zamac.

Screw nipple steel.

Sheath, steel wire with inner and outer plastic coating.

body POM.

Nipple Zamac.

Screw nipple steel.

Version

Bowden cable sheath and body black.

Screw nipple electro zinc-plated.

Screw nipple electro zinc-plated.

Show more

Show less

Description

Material

Wire cable stainless steel.

Sheath, steel wire with inner and outer plastic coating.

body POM.

Nipple Zamac.

Screw nipple steel.

Sheath, steel wire with inner and outer plastic coating.

body POM.

Nipple Zamac.

Screw nipple steel.

Version

Bowden cable sheath and body black.

Screw nipple electro zinc-plated.

Screw nipple electro zinc-plated.

Note

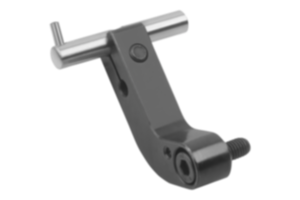

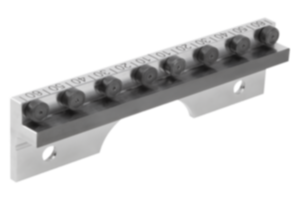

Bowden cables transfer the traction force and are used in combination with a release as a remote control.

There are different lengths available to select from. The Bowden cable can be shortened as required during installation to ensure a perfect fit in the respective application.

Note the following points when installing Bowden cables:

The length of the free end of the cable can change due to layout angle, bend radius and load factors.

When laying the cable, take particular care to ensure that the bend radius is not below the minimum value, which in this case is R = 65 mm. A too small radius can lead to increased wear and higher friction. During installation, avoid bending the cable more than the minimum value as this can cause damage to the casing. Also, the casing is designed only to support pressure forces. If pulled too sharply, the inner coil will be stretched and permanently damaged.

Tensile strength 1000 N max.

There are different lengths available to select from. The Bowden cable can be shortened as required during installation to ensure a perfect fit in the respective application.

Note the following points when installing Bowden cables:

The length of the free end of the cable can change due to layout angle, bend radius and load factors.

When laying the cable, take particular care to ensure that the bend radius is not below the minimum value, which in this case is R = 65 mm. A too small radius can lead to increased wear and higher friction. During installation, avoid bending the cable more than the minimum value as this can cause damage to the casing. Also, the casing is designed only to support pressure forces. If pulled too sharply, the inner coil will be stretched and permanently damaged.

Tensile strength 1000 N max.

Scope of delivery

Wire cable with nipple, sheath, body and screw nipple.

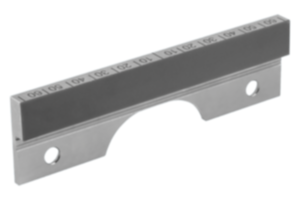

Drawing reference

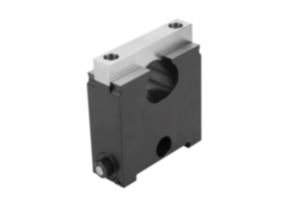

1) body

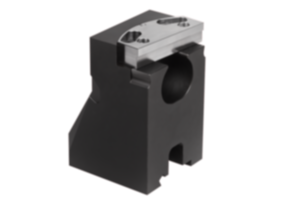

2) Screw nipple

3) Body 1x19

4) Nipple

5) Sheath

6) Wire cable

2) Screw nipple

3) Body 1x19

4) Nipple

5) Sheath

6) Wire cable

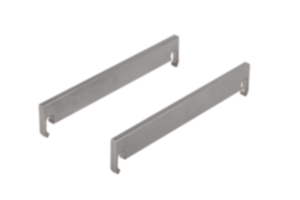

Accessory

Release K1481 or snap locks K1851.

Important note on downloading CAD models

You must log in before you can download our CAD models. If you have not yet created an account, please register under "My account" (right-hand side of the screen) and follow the instructions.